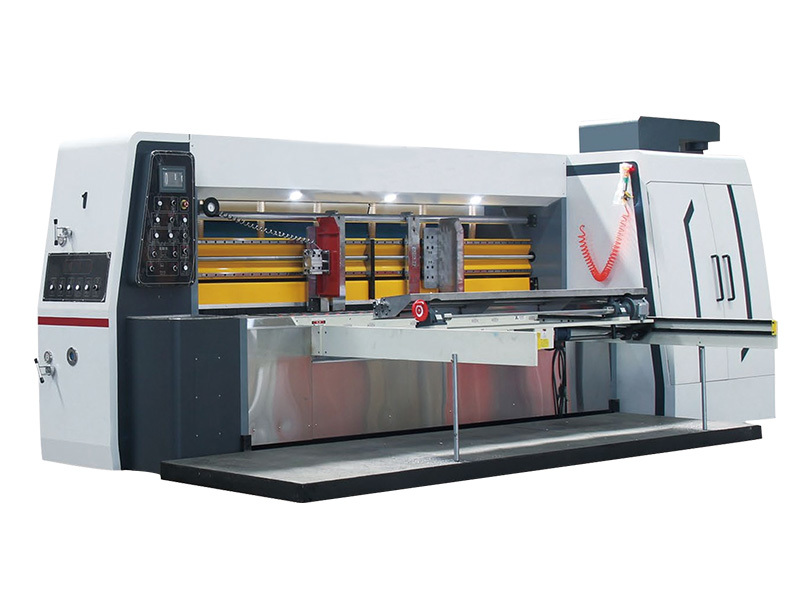

high speed color flexo printing &slotting & rotary die-cutting machine

Designed According the high request and the reliable function, the operation of the machine is humanization, can accomplish the setting, revision, implement, replacing and memories function in a shot time, and display with a exact data.

key word:

Classification:

high speed color flexo printing &slotting & rotary die-cutting machine

Performance of the main mechanisms:

● Designed According the high request and the reliable function, the operation of the machine is humanization, can accomplish the setting, revision, implement, replacing and memories function in a shot time, and display with a exact data.

● All the drive rollers adopted high quality steel materials, hard chromium plating and the surface treated by lapping finish.

● The drive gears adopt high quality alloy steel, after heat treatment and lapping finish.

● The main drive roller adopt keyless connect, decrease the connection gap, guarantee the printing presicion.

● Lubricate oil automatic balance device, keep the equal oil level equal in each unit.

● Computer touch screen, with storage order, zero, memory and other functions.

● Use sun feeder for feed the cardboard.

● Customer can chose use steel anilox roller or ceramic roller,the lines of the anilox roller ac so can be chosed accord the customer use

● The machine adopts schneider imported low-voltage electrical appliances, stable and reliable performance.

FEEDER:

● Lead edge feeder system, inverter adjust air volume, feeding in precision and steady.

● Double feeding roller model, quick replacement mechanism for the first feeding rubber roller, with spring adjustment function, it can prevent distortion and to ensure accurate feeding of cardboard.

● Brushes and suction device remove dust from board surface.

● Touch screen displays production speed and quantity.

● Adjust the feed interval by manual.

Use and characteristics:

● Designed According the high request and the reliable function, the operation of the machine is humanization, can accomplish the setting, revision, implement, replacing and memories function in a shot time, and display with a exact data.

● All the drive rollers adopted high quality steel materials, hard chromium plating and the surface treated by lapping finish.

● The drive gears adopt high quality alloy steel, after heat treatment and lapping finish.

● The main drive roller adopt keyless connect, decrease the connection gap, guarantee the printing presicion.

● Lubricate oil automatic balance device, keep the equal oil level equal in each unit.

● PLC with touch-screen multifunction control, repeat order store and auto reset system after cleaning.

● Pneumatic elastic paper feed roller, does not destroy the strength of corrugated board.

● Side baffle plate is additionally provided with a pneumatic device shoot Qi cardboard transverse positioning more accurate avoid wasting.(optional)

● Rapid change version of the device, saving the shift time.

Technical parameters

|

Modle |

920 |

922 |

1224 |

1228 |

1628 |

1632 |

1636 |

1832 |

|

|

Max. machine speed(pcs/m) |

400 |

400 |

320 |

280 |

260 |

220 |

220 |

150 |

|

|

Max.feeding size(mm) |

950x2100 |

950x2300 |

1250x2500 |

1250x2900 |

1650x2900 |

1650x3300 |

1650x3700 |

1800x3300 |

|

|

Min.feeding size(mm) |

260x650 |

260x650 |

360x650 |

360x650 |

450x650 |

450x650 |

450x650 |

480x650 |

|

|

Max.printing area(mm) |

900x2000 |

900x2200 |

1200x2400 |

1200x2800 |

1600x2800 |

1600x3200 |

1600x3200 |

1800x3200 |

|

|

Min.slotting interval |

Normal |

160x160x160x160 |

160x160x160x160 |

160x160x160x160 |

160x160x160x160 |

160x160x160x160 |

160x160x160x160 |

160x160x160x160 |

160x160x160x160 |

|

Reverse |

260x60x260x60 |

260x60x260x60 |

260x60x260x60 |

260x60x260x60 |

260x60x260x60 |

260x60x260x60 |

260x60x260x60 |

260x60x260x60 |

|

|

Max skip feeding size (mm) |

1100x2100 |

1100x2300 |

1500x2500 |

1500x2900 |

1800x2900 |

1800x3300 |

1800x2700 |

2000x3300 |

|

|

Printing plate thickness(mm) |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

|

FEEDER function:

● Lead edge feeder system, inverter adjust air volume, feeding in precision and steady.

● Double feeding roller model, quick replacement mechanism for the first feeding rubber roller, with spring adjustment function, it can prevent distortion and to ensure accurate feeding of cardboard.

Brushes and suction device remove dust from board surface.

● Touch screen displays production speed and quantity.

● Adjust the feed interval by manual.

Slotting function:

● Single-axle double-knife structure is adopted, and the back-knife can be set by computer and adjusted electrically by hands.

● The five-knife set can all be moved, and the adjustment clearance can be set by computer and adjusted electrically by hands.

● The arbor and pressure line axle both adlpt hard twice precision grinding.

● There's the elastic corner-cutting kinfe. The third, fifth and seventh cardboard don't need to be adjusted.

● Manual double base adjustment pressure wheel clearance, quick and convenient adjustment;

● The phase fixation adkpts electromagnetic brake institution. When the machine and stage separate or adjusting the phase, keep the front knife plate fixed;

● The touch displaying screen is equipped, which makes date setting and control easier.

Printing department function:

● Printing rollers and embossing rollers are made of high-quality steel with surface grinding and hard chrome plating. Dynamic and static balance correction, stable operation.

● Using the hanging plate mechanism, the installation is convenient and fast.

● The loading and unloading printing plate is equipped with a foot switch or the operation surface to control the forward and reverse rotation, which is fast and convenient.

● With the paper feeding system, there is an automatic lifting and lowering anilox roller, and the anilox roller automatically descends to contact with the printing plate when the paper is fed.

When the paper is stopped, the anilox roller automatically rises and separates from the printing plate.

● The phase adopts electromagnetic brake fixing device, which has intelligent zeroing, dynamic and static reset can be shortcut.

● Printing phase adopts PLC touch screen control and electric digital 360-degree adjustment.

● The self-locking structure of the paper guide roller traverses quickly, and the pressure is intermittently self-locking and adjusting device.

Die cutting function:

● the rubber roller adopt mechanical control the position move left and right.

The movement distance is 40mm.

● The phase of the die-cutting unit adopt PLC and electric 360°adjust, accord the error to input the adjust data, can be adjusted while the machine running or stop.

● (optional) The horizontal moving of the die roller adopt PLC and electric adjustment, input the adjust data accord the error, adjusting distance is 10mm.

● The space adjustment between rubber roller and die roller adopt self-locking structure, with cylinder big scope quickly adjust, decrease the rubber wear, increase the rubber life.

● The space adjustment between the feed rollers adopt self-locking structure.

● The unique speed compensation device can make the rubber roller rolling running with the die roller, make the surface speed of the rubber cushion is completely controlled by the die roller, the shape of the carton sheet will absolutely equal to the die pattern.

● There is a rubber repair device with the machine, the rubber can be used after be repaired.

PREV

HCL- automatic flexographic printing, die-cutting folder binding

Recommended products